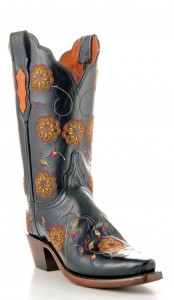

Handmade Lucchese Boots

Handmade footwear is truly unmatched in comfort, appearance, and quality. In order to achieve this, however, the boots must go through a laborious and intricate process. Handmade Lucchese boots have over 100 steps in their manufacturing process and are touched by hand at virtually every step of the way.

The art of boot making is a very intricate process and Handmade Lucchese Boots have been perfecting their technique since their humble beginnings in 1883. Every single Lucchese Classics, Lucchese 2000, and Lucchese 1883 boots have been made by hand since the company’s inception. There are over 100 steps in the construction process, and Lucchese boots are touched by hand at virtually every stage. Only the finest leathers are used in the construction of these boots, each piece is inspected by hand to ensure the perfect size, quality and match. It is then cut to specification for any given style of boot. The leathers are piped by hand and lined by hand as well. After the boots are stitched and corded by hand, the leather uppers are trimmed and attached by hand to ensure excellent fit that is characteristic of Lucchese.

Next the boots are hand-lasted to the insole and hand fitted to the boot upper. In the hand lasting process, boots are made wet after being fitted to the last and then put in a heated room for at least 24 hours in order to change the memory of the leather to ensure the unmatched comfort that Lucchese is known for.

The excess moisture is wicked away in the heated room and the leather retains a new shape. The outsole and heel are then applied and the lemon wood pegs are inserted into the sole by hand, a tradition that dates back to the 1800s. The leather is then conditioned, cleaned and hand painted by skilled artists and shipped to retailers.

waaov